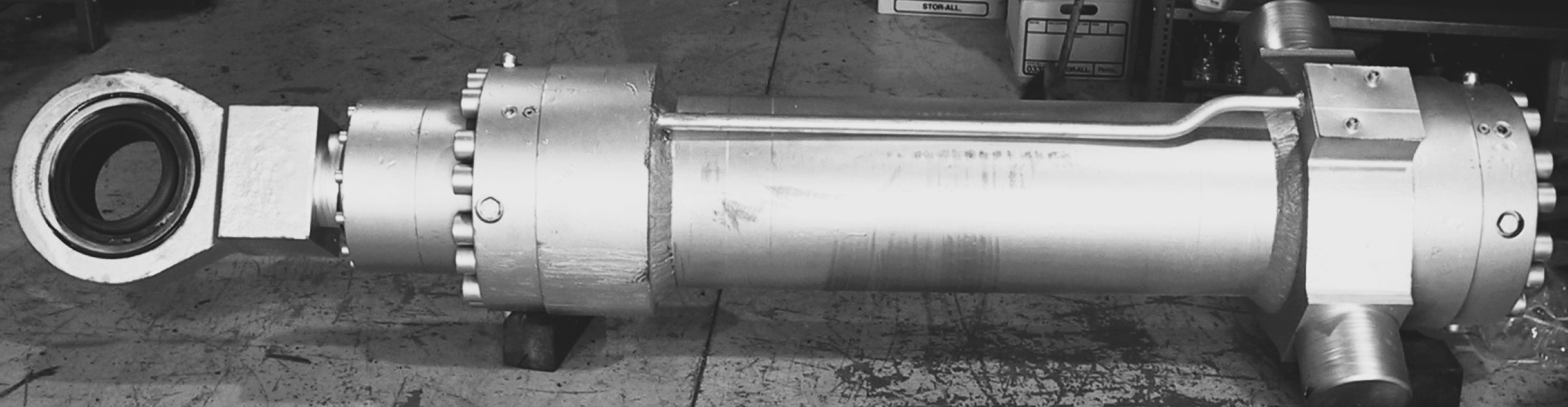

Mineral extraction and processing are among the oldest industries in the country and date back long before Europeans settled in North America. Indigenous populations extracted copper, silver, gold, cobalt, obsidian and flint for a variety of reasons in varying quantities throughout history. The flood of European immigration during the 17th and 18th centuries was heavily influenced by the availability of natural resources and the immense wealth associated with discovering a viable deposit. Over the next 200 years, Canada utilized its vast natural resources to grow into an economic and political superpower rivaling countries with much larger populations. Modern Canada remains the richest natural resource hub in the world with more variety and viability than any other country. Unfortunately, a lack of understanding regarding the long-term implications of previously acceptable mining practices have left many remote ecosystems destroyed which has soured the relationship between the industry and its stake holders. As a result, environmental stewardship has become the most important aspect of mining at present, which includes cleaning up the messes made by operations of the past. There is no evading the short-term destruction of the local ecosystem but the ultimate goal of reclamation is to leave the area so it can be reclaimed by the local ecosystem and seamlessly integrate back into the surrounding area. For nearly 30 years, we at MacroMotion have supplied design firms like Outotec and EPCM with hydraulic, pneumatic and fluid conveyance products through our distribution networks and have manufactured/altered countless custom products that have been integrated into stripping, extraction and processing systems around the world. We can help you control dust, limit noise, reduce water consumption, reduce the production of non-neutral tailings, improve outdated systems and maintain current ones. Please see our case studies below for detailed examples of some of our past projects.